Country's heavy instrument installed Chinese core

- classification:2022

- Author:JIA ShaoXiu

- source:

- Time:2022-11-09

- Views:0

SummarySuccessful Operation of Domestic Dry Gas Seal for Cracking Gas Compressor of Gulei Petrochemical 800,000t/a Ethylene Plant

Country's heavy instrument installed Chinese core

SummarySuccessful Operation of Domestic Dry Gas Seal for Cracking Gas Compressor of Gulei Petrochemical 800,000t/a Ethylene Plant

- classification:2022

- Author:JIA ShaoXiu

- source:

- Time:2022-11-09

- Views:0

On October 3, 2022, when the whole country celebrated the National Day, our company received an emergency notice from Gulei Petrochemical that its 800000 t/a ethylene plant failed to start up three times due to the leakage of imported dry gas seals. We urgently need to provide dry gas seals to find out the causes, solve the problems and ensure the start up!

The scene is the battlefield, and rescue is like fighting a fire!

On the same day, Sinoseal immediately determined the technical director and service personnel. At the same time, according to the data provided by Gulei Petrochemical, Sinoseal analyzed the reasons, checked the parameters and inquired about the replacement products.

On October 4, Jia Shaoxiu, the deputy manager of the sales department, led the team. Liu Jianrong, Yang Fei, the dry gas sealing experts, and Dong Guangxu, Bai Shiqiang, Zhang Longbao, the senior service personnel, and Wang Yong, the sales engineer. The seven member team rushed to Gulei Petrochemical in an emergency. He Fang, the general manager, personally supervised. In the evening, we immediately held a technical docking meeting with experts from Gulei Petrochemical until late at night to conduct in-depth discussion and analysis based on the performance of dry gas seal leakage in the third start-up of Gulei Petrochemical, central control data, etc., and determines the solution and work progress.

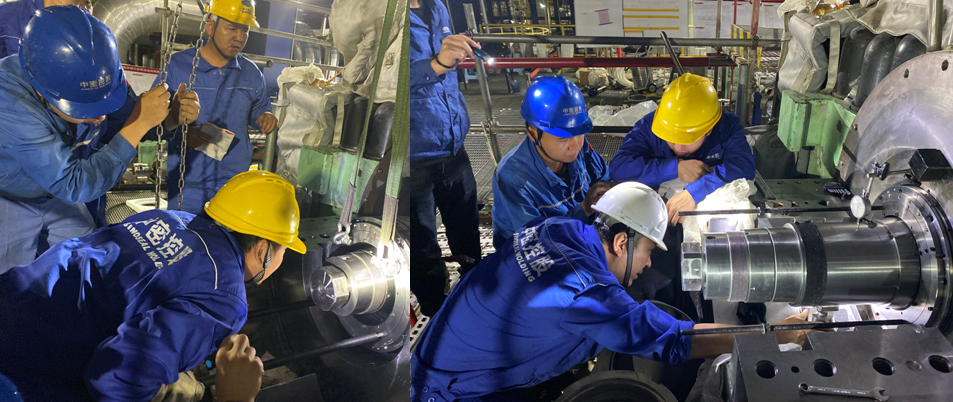

In the early morning of October 5, Dong Guangxu, Bai Shiqiang and Zhang Longbao went to the site to clean the dry gas seal chamber and pipeline, and connected with the inspection and installation company. Liu Jianrong checked the details of the original failed seal, and Yang Fei checked the on-site control system configuration, instrument range, operation specification, central control curve, etc.

On October 6, a total of 6 sets of dry gas seals for 3 cracked gas compressors were installed, and the static pressure test was qualified.

On October 7, we had in-depth communication with experts of Gulei Petrochemical on startup conditions and system settings again, and determined the startup plan.

In the morning of October 8, Gulei Petrochemical started pipe warming, low-speed turning and nitrogen commissioning, and everyone's heart was raised! At 9:30 p.m., the unit was accelerated to 3600RPM, the process gas was switched on October 9, and the ethylene plant produced qualified products on October 10! The whole process of dry gas seal operation is stable, and all parameters reach the design level!

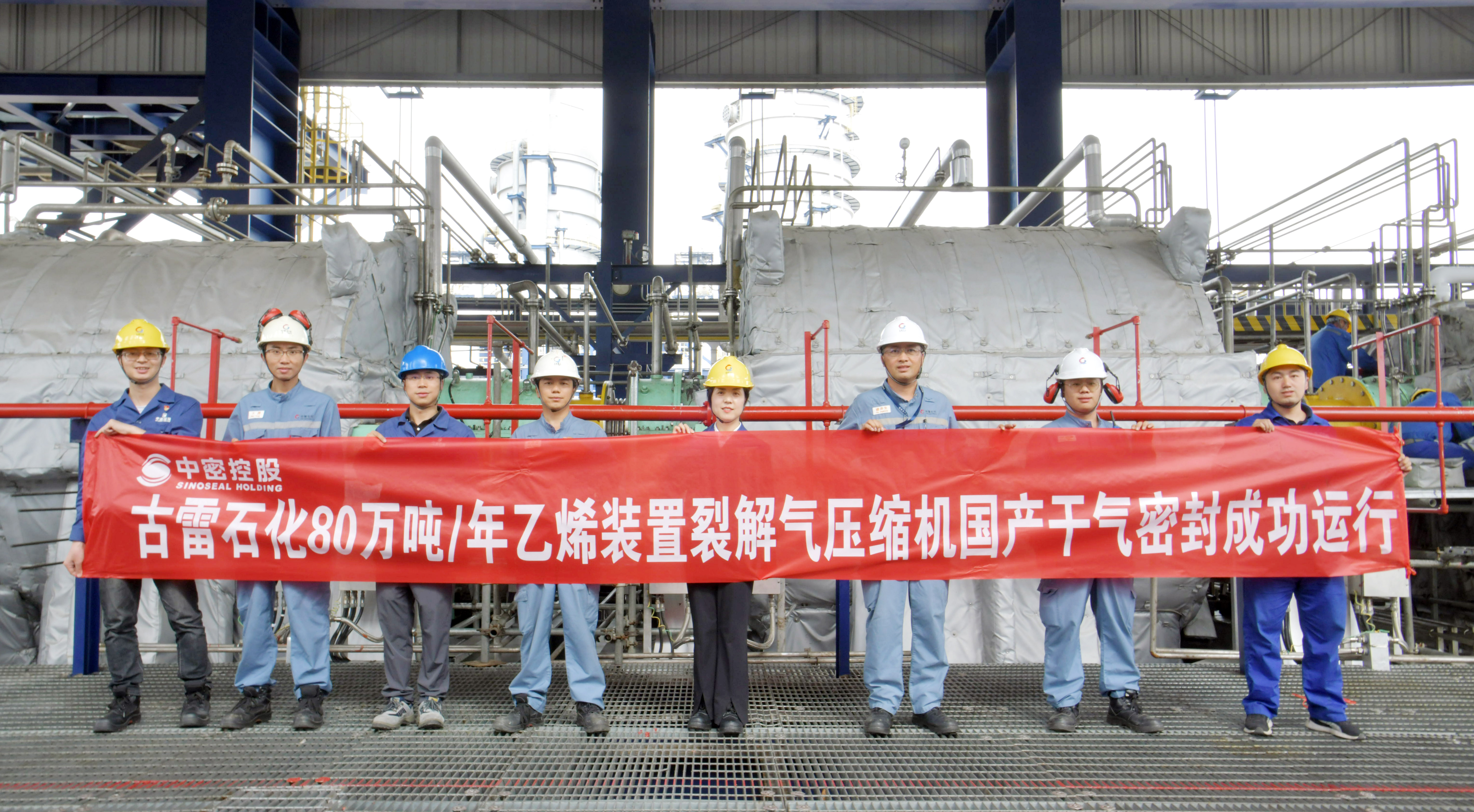

So far, the cracking gas compressor of Gulei Petrochemical's 800000t/a ethylene plant has been running steadily for a month, and all indicators have reached or exceeded foreign products!

The production capacity and level of ethylene mark the development level of a national petrochemical industry. For a long time, China's three unit dry gas seals with a million tons of ethylene have been imported. In order to ensure the national energy security and install Chinese core into the country's most important equipment, Sinoseal bravely provoked the responsibility of China's dynamic seal industry to catch up with the world level. We insisted on technological innovation and independently solved the key parts of much major equipment. In 2020, Zhongke Refining&Chemical will provide 800,000t/a ethylene with medium density dry gas sealing products, and it will operate safely for more than two years, solving the problem from scratch! After Zhongke, Sinoseal has also supported Wanhua, Zhenhai, Hainan, Maoming, Longyou and other ethylene projects, all of which have been put into operation except Hainan. This time, we took orders from Gulei Petrochemical in a crisis, and we overcame the difficulties. The success of a successful start-up has made the performance of dry gas seal products from excellent to excellent, which once again proves that Sinoseal’s one million ton ethylene dry gas seal can better adapt to various extreme and complex working conditions, and its reliability exceeds the international advanced level!

In addition, Sinoseal also overcame the choke products such as high pressure dry gas seal of West East Gas Transmission Pipeline, ultra-high pressure dry gas seal of oil refining unit, supercritical CO2 dry gas seal, and 50000 rpm ultra-high speed dry gas seal, and realized industrial operation.

In the future, Sinoseal will continue to increase investment in research and development, continue to promote industrial strength, unswervingly carry out technological innovation, promote high-quality development, shoulder the banner of China's sealing cause, and make greater contributions to the comprehensive localization of national major equipment and the development of China's energy industry.

扫二维码用手机看

Recommend

- Promote Green Development and Build a Beautiful China - CCUS Project supported by Sinoseal successfully put into production 2023.06.08

- Ingenuity boosts quality ,innovation makesremarkble——Warmly congratulate the 3 people of Sinoseal for getting the title of "Zhuge Artisan". 2023.01.08

- Sinoseal Mobilization Meeting of 2023 2023.01.04

- Good news of large rotating equipment—CM22 split mechanical seal 2022.12.26

- Innovation lets Sinoseal Stand Out 2022.11.21

- Country's heavy instrument installed Chinese core 2022.11.09

Contact

Email: export@sns-china.com

International sales: +86-028-85373902

Address: No. 8, 4th Wuke West Road, Chengdu City, Sichuan Province,China

Sinoseal Holding Co., Ltd. is a Chinese listed company and a leader in China’s Fluid Sealing Industry. Sinoseal has transformed its 40 over years of research and development experience into a professional company specialized in the production and a provider of overall sealing solutions for its customers. With our strong technical strength and advance technology and equipment used in manufacturing , Sinoseal’s products and services enjoy a good reputation across the industries it serves in China.

Copyright © 2020 SINOSEAL HOLDING Co., Ltd. All rights reserved. 蜀ICP备05014698号